PRODUCTS

Keep Consistent Good Quality as First Priority and Satisfy the Needs of Customers is the goal that Grand pursues

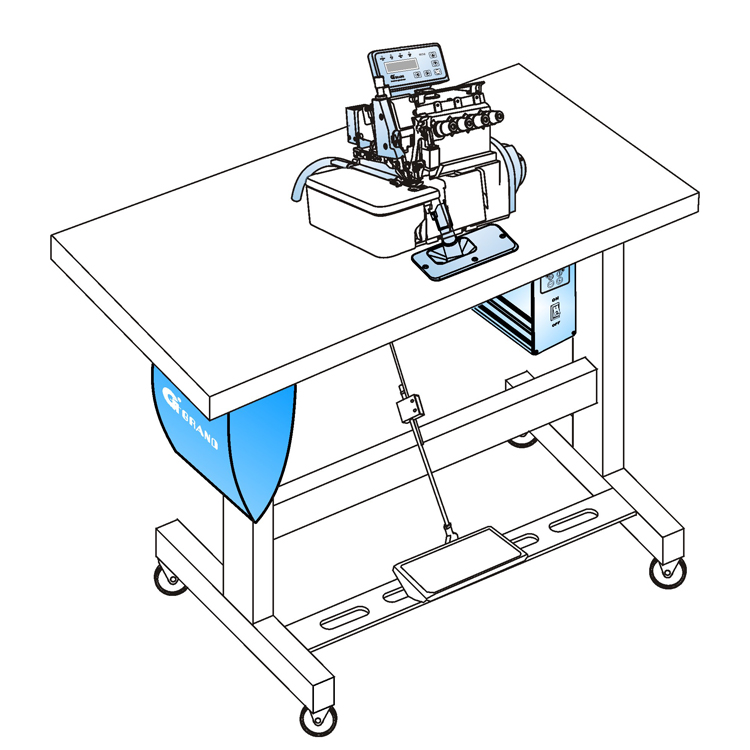

The schematic diagram of component installation is as follows:

|

product name: |

Microcomputer direct drive motor automatic induction suction thread trimming device (direct drive motor + two or three pairs of radio-sensors + pneumatic thread cutter group + presser foot + air suction dust collection device, equipped with Yamato overlock sewing machine series) |

| Product number: | GMD1-GTC-8-P-YAMATO |

| Features: |

1.Using servo direct drive motor and control system, super power saving;

2. Electric eye sensor, which can automatically lift the presser foot to run and sew to achieve time-saving effect;

3. Electric eye sensor, which can set the number of stitches to control the automatic stop of sewing suction and thread trimming to save money;

4. Inductive induction, the number of stitches can be set to control the two sections of automatic suction before and after sewing to achieve air-saving effect;

5. Pneumatic thread cutter group is used. The angle of the fixed cutter can be adjusted to prolong the service life of the cutter body. The thread cutter can be used simultaneously without maintenance.

6. No need for skilled employees, let new and old employees stand on the same starting line.

7, save time, materials, labor, comprehensive production capacity increased by about 30%.

8. This product is suitable for heavy machine, Yamato, Pegasus, Yinjian and domestic overlock sewing machines.

9. If there are special circumstances, please contact the engineering department directly.

|

Compared with similar KS \ KH products, this product has many advantages:

| GTC series thread cutting device | KS KH tangent device | |

| 1 | With button type manual thread trimming function, easy to use in special situations | No manual trimming function |

| 2 | Can cut front stitches | Can't cut front suture |

| 3 | No need to stop cutting seams, can increase output by 30% | Must stop cutting suture |

| 4 | Back cut stitching length can be selected | Back cut stitching cannot be selected in length |

| 5 | Consistent stitch length after cutting to improve product quality | Uneven stitch length after cutting |

| 6 | Can cut elastic bands, shoulder straps, etc. | Elastic bands, shoulder straps, etc. cannot be cut |

| 7 | Single process sewing can save 16CM line | Can't save line |

| 8 | Suction air only at the moment of tangent, saving energy and reducing noise | Always sucking air while sewing |

| 9 | Even newbies can operate | Must be skilled |

It is suitable for the sewing operation of pants, pajamas, sportswear, work clothes, blouses and handkerchiefs.

Contact Us

Add: NO. 136,Qiwan Roard North, East District, Zhongshan City, Guangdong Province, China

Fax:86-760-88414668

E-mail:sale@usa-grand.com

SCAN QR CODE

Copyright(C) Grand int'l enterprise(u.s.a) INC. All rights reserved | Powered by www.300.cn | 粤ICP备05031502号